MassEducation22

Well-known member

- Joined

- Sep 4, 2019

- Messages

- 47

Hello all fellow EBMM members,

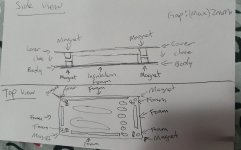

I just had an idea for a modification in regards to the cavity/pickguard covers, with the tools of sticky adhesive/superglue: durable, super strong and super thin mini neodymium magnets and mini insulation foam tape, instead of screws. The gap would only be 2mm max, which is covered by the foam itself. I was wondering if this would be safe to use.

Please see my (attached thumbnail) concept drawing.

Thanks!

I just had an idea for a modification in regards to the cavity/pickguard covers, with the tools of sticky adhesive/superglue: durable, super strong and super thin mini neodymium magnets and mini insulation foam tape, instead of screws. The gap would only be 2mm max, which is covered by the foam itself. I was wondering if this would be safe to use.

Please see my (attached thumbnail) concept drawing.

Thanks!

Attachments

Last edited: